Way to Unlock PLC-password in 5 minutes. However, PLC would be a Programmable Logic Controller. Moreover, PLC would be a laptop that’s a lot designed to work faithfully below harsh environments. Therefore, Like extreme temperatures, dry, wet, and dust-covered things.

This system is employed to alter industrial processes like mechanical system-producing plants and alternative process plants.

PLC shares several options of the pc. Programmable logic Controller plays an important role within the field of automation.

It will be programmed following the operational claim of the method.

PLC ceaselessly monitors the input values from numerous input sensing devices programmable Logic Controller accommodates 5 elements-

Input and Output module

Power provide

Central process Unit (CPU)

Communication interface Module

Rack or chassis

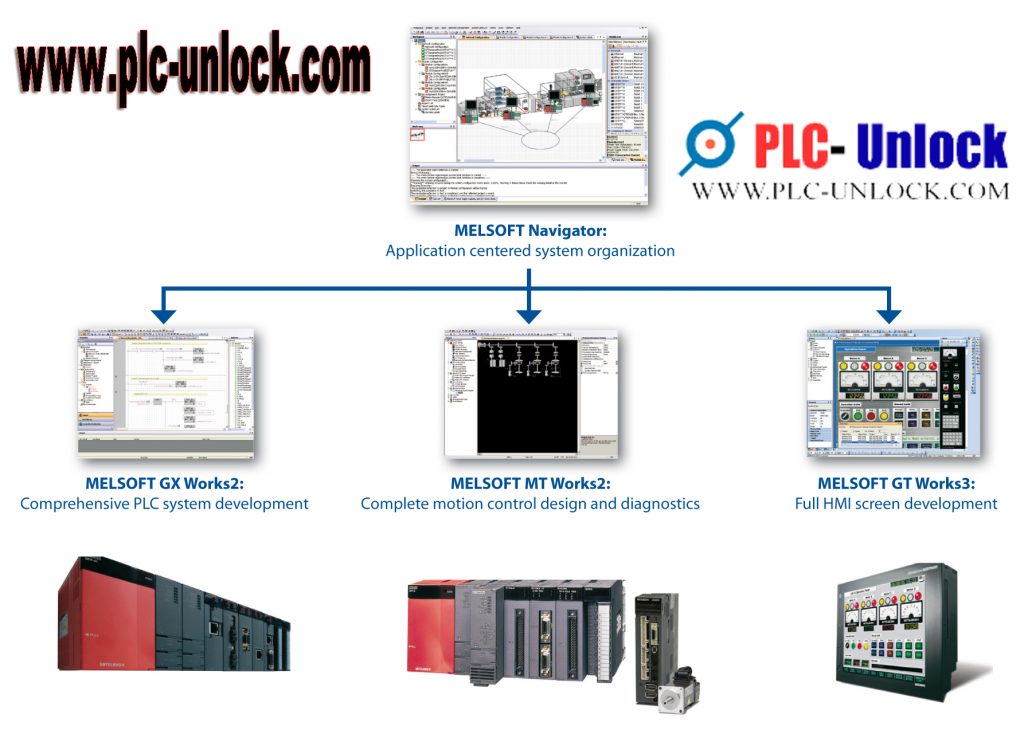

There square measure numerous varieties of notable PLC brands within the world.

Allen Bradly

Mitsubishi

Siemens

Delta

ABB

LS

Omron

Panasonic

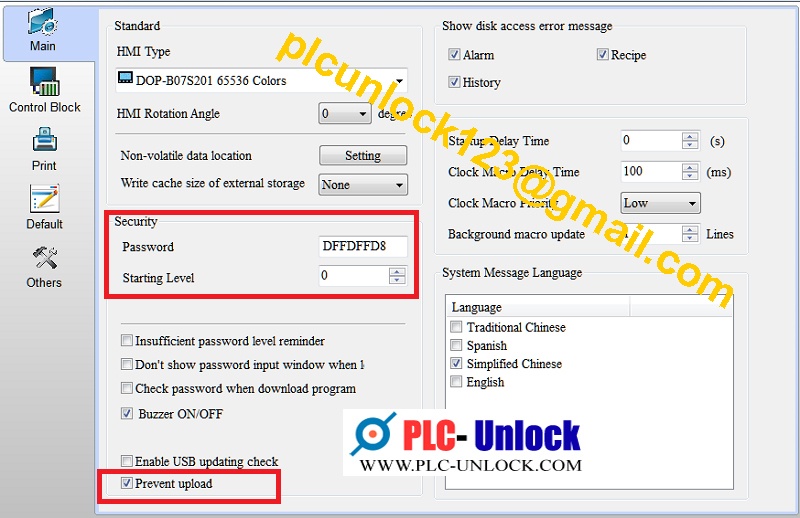

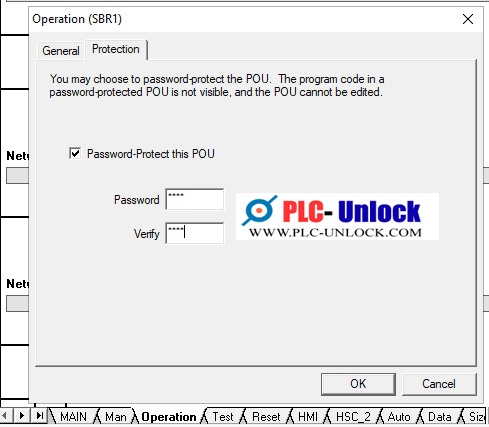

Without the on top of PLC complete. There are a lot of brand names of Programmable Logic Controller PLC passwords. Will limit programming modules. Programming tools, monitoring, interface to scan and write procedures, amendment the present values, and so on, to guard the program. Programmer with unlock kit

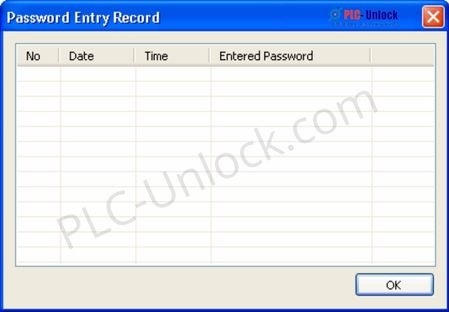

Unlock PLC password is that the primary thought if the password is lost when setting the password.

way to Unlock PLC-password:

The password protection prominence integral AN exceedingly in a very Programmable Logic Controller. As a result of a PLC password is required to guard access by an unauthorize person.

For this reason, unlock the Mitsubishi PLC password is require this protection. Isn’t the essential feature of the Programmable Logic Controller?

Many of the PLC password protection will be removed by removing. The battery and taking away the facility a few explicit times.

Panasonic plc password crack, In most cases, the protection is remove if the protection still presents, then take away the processor for generally.

To cater to clients’ desires. In other words, we tend to square measure engaged in giving to unlock PLC password recovery service from Asian country Automation Technologies.

We open all types of PLC passwords, like Siemens, Mitsubishi, Delta, LS, Omron, LG, Allen Bradly, and others.

We provide this password recovery service to the customer’s requirements, and client satisfaction knowledgeable engineers of Asian country Automation Technologies invariably engaged in operating for unlocking PLC password.

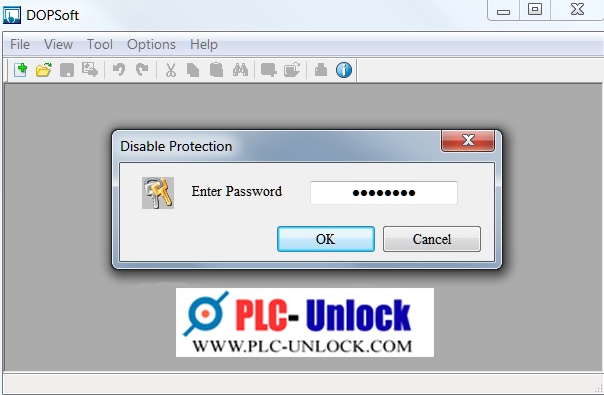

Plc Password Crack:

How To Unlock PLC password

Programmable Logic Controller password is a massive bother for machine failure, and program backup our mission is to rescue this drawback.

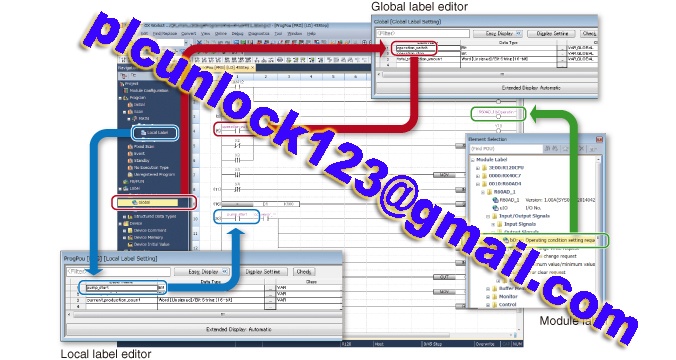

Suppose you have got a Mitsubishi letter of the alphabet series PLC, however, it’s in a very latch condition, if you would like to unlock it then use the USB knowledge mortal to trace USB knowledge pockets and search through the up knowledge streams. It is a

PLC password crack is offer in Asian country Automation technologies ton of ability engineer is prepared to supply your expected service.

PLC uses one reasonably protected system; it’s conjointly troublesome to crack passwords.

Programmable logic Controller password cracking is that the method of covering passwords from the knowledge that has been keep or transmitted by an ADPS.

The purpose of PLC password cracking may well be to assist a user to recover a forgotten password or install a replacement password is a smaller amount of a security risk and gain unauthorized access to a system.

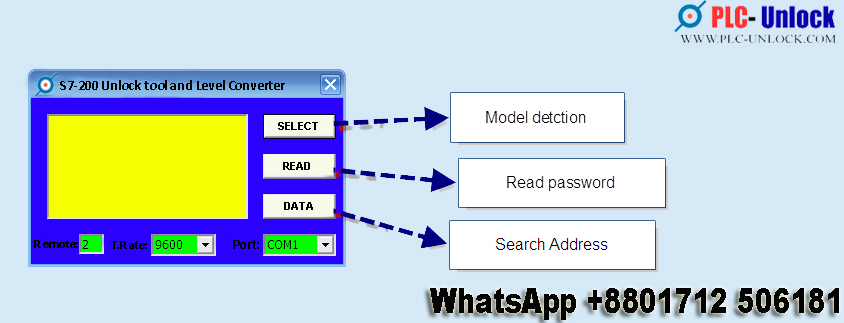

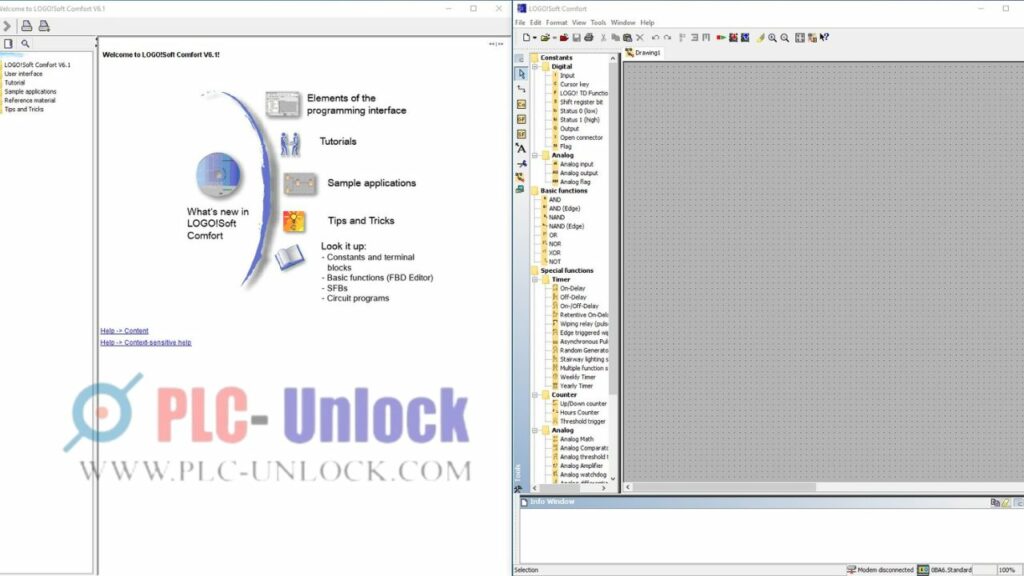

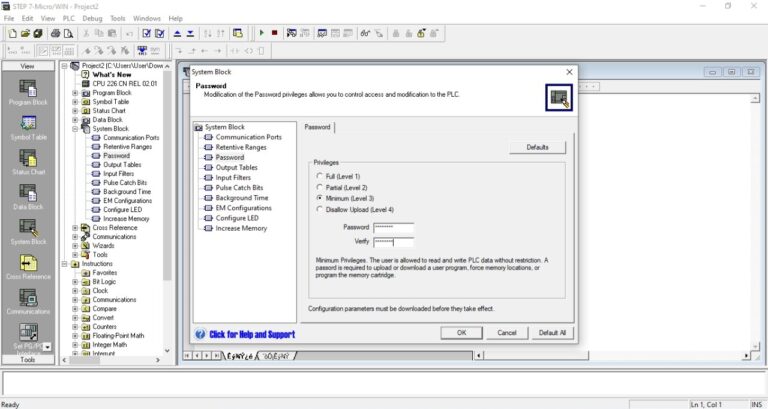

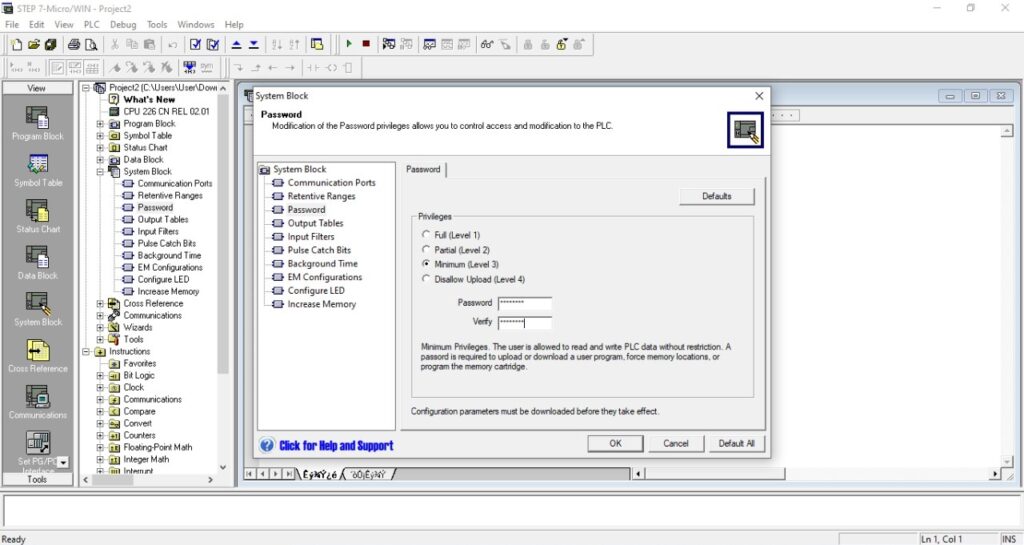

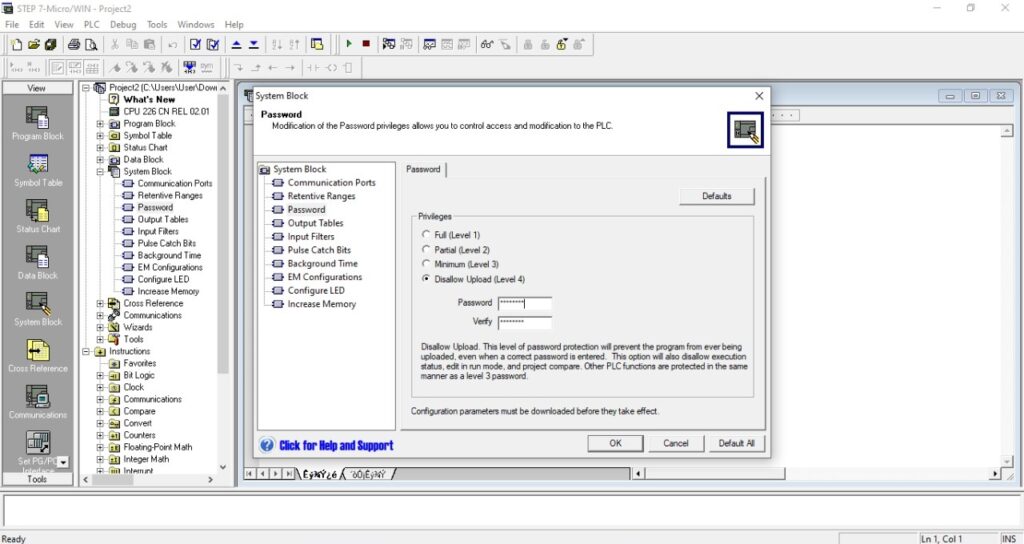

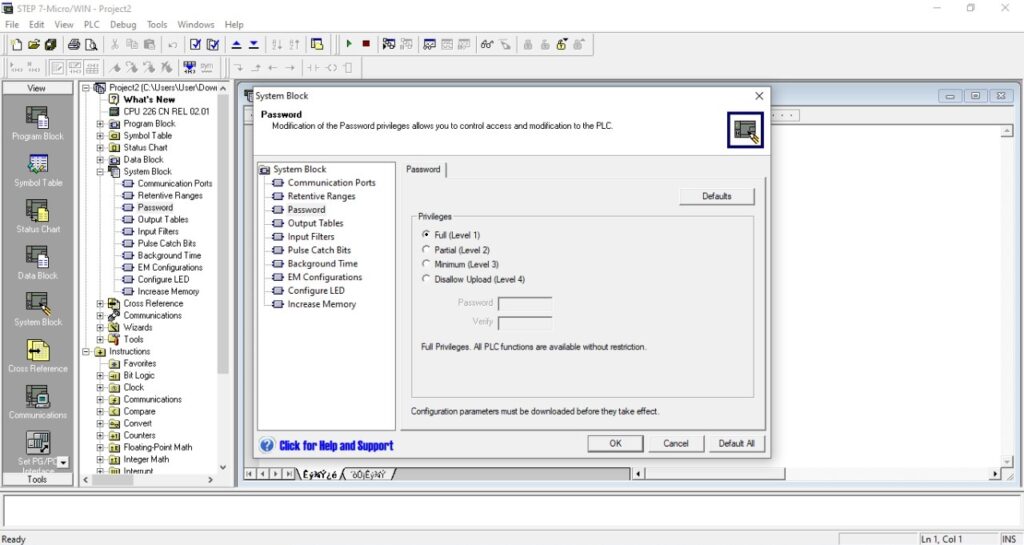

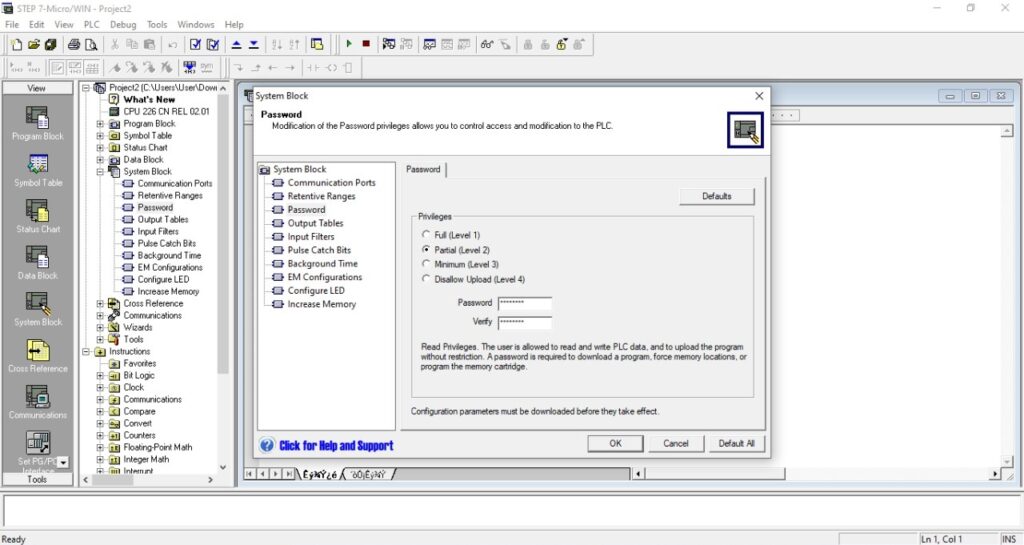

Siemens PLC Password Break:

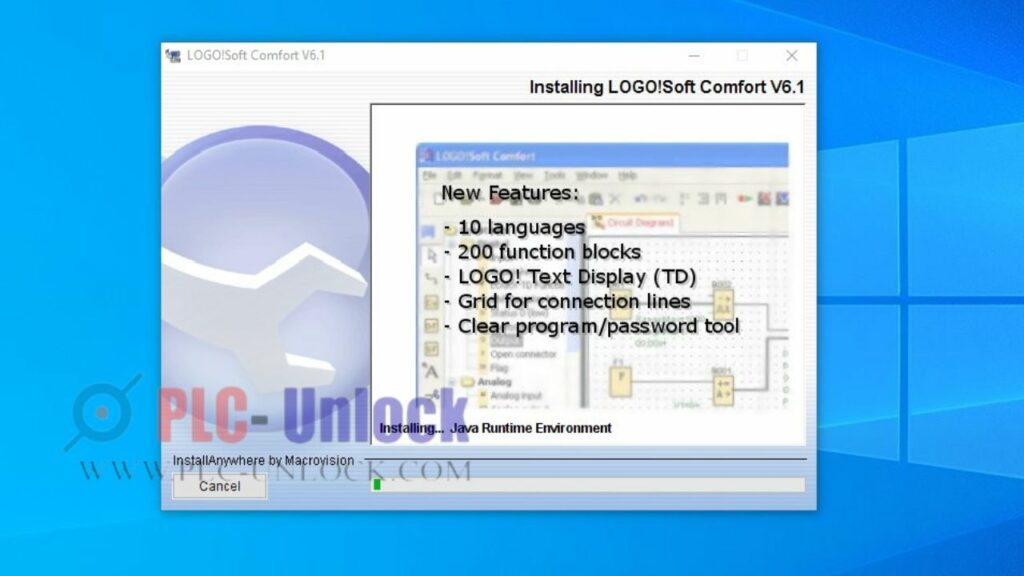

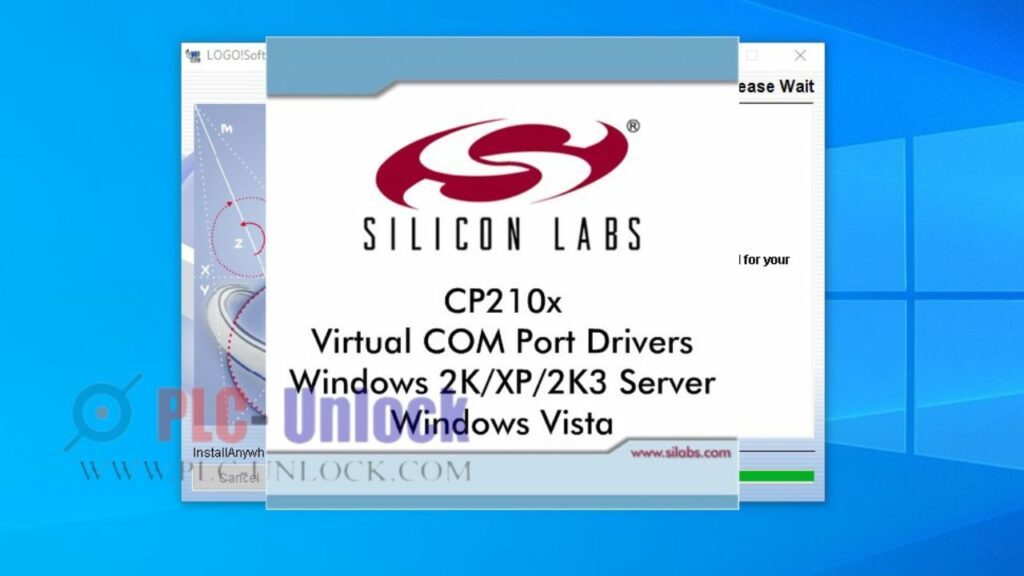

There is a great deal of PLC complete within the world Siemens is that the most supposed PLC complete within the world owing to their diversity of merchandise and that they square measure useful from low-level to a high-level application within the business. For this reason, we tend to square measure discussing Siemens PLC password break

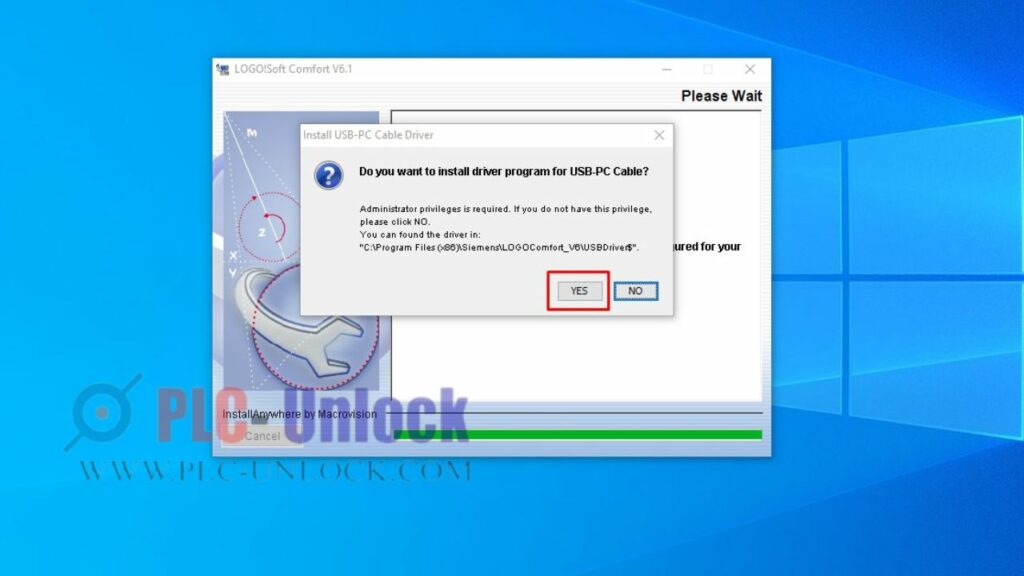

Siemens PLC is a lot quicker than alternative Programmable Logic Controllers. Unlocking the PLC password is that the primary thought during this section.

Whatever it’s conjointly difficult to crack the PLC password as a result of they’re extremely protect. If you would like to interrupt Siemens PLC’s password, then you have got to follow this instruction, which is below.

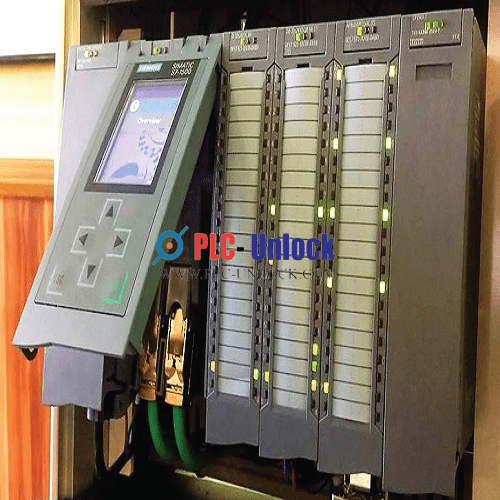

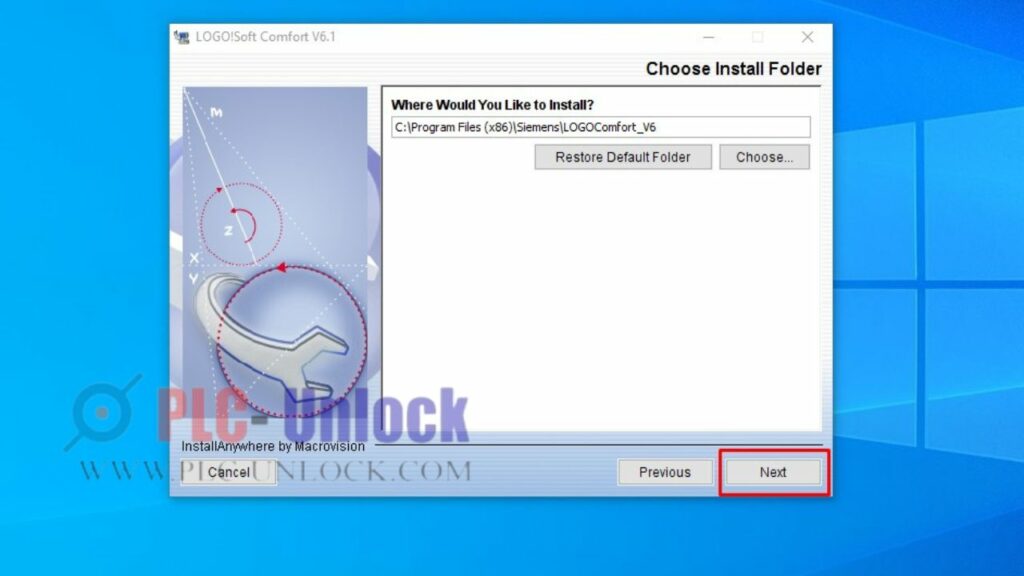

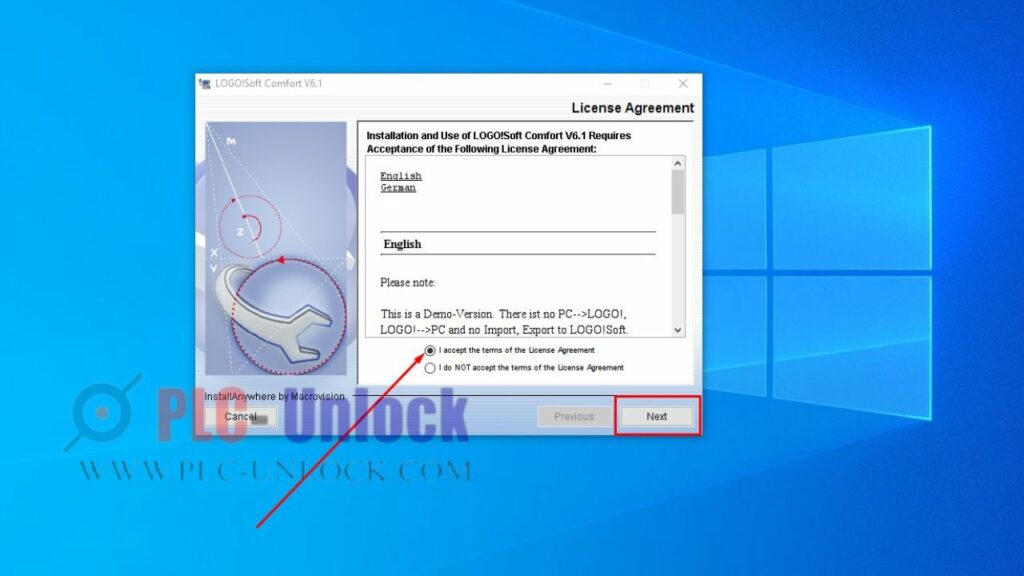

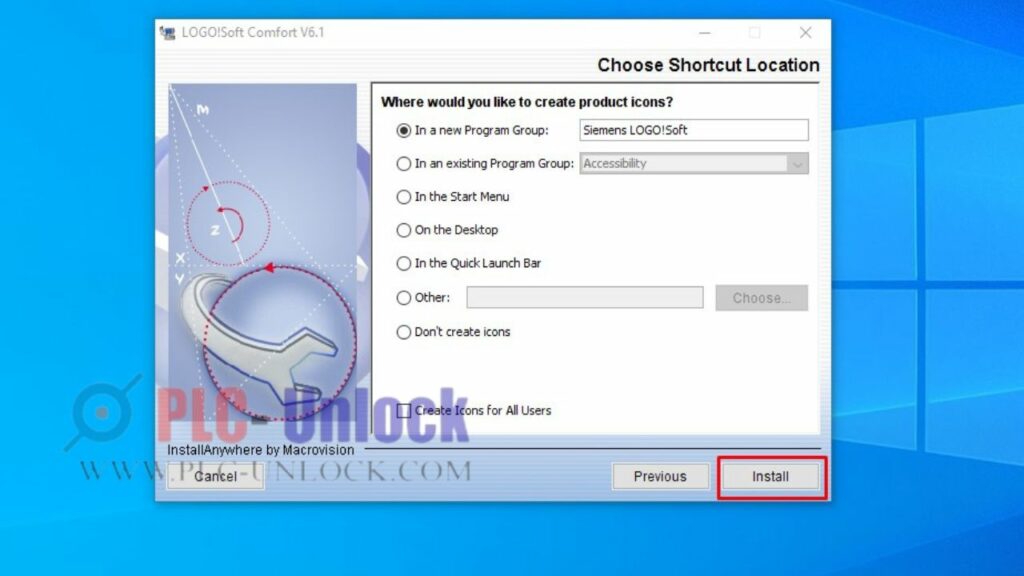

First of all, realize a file name for your project.

Open SUB BLK.DBF with Microsoft workplace access 2007

You ought to realize a password column in it.

Change zero – three all save files.

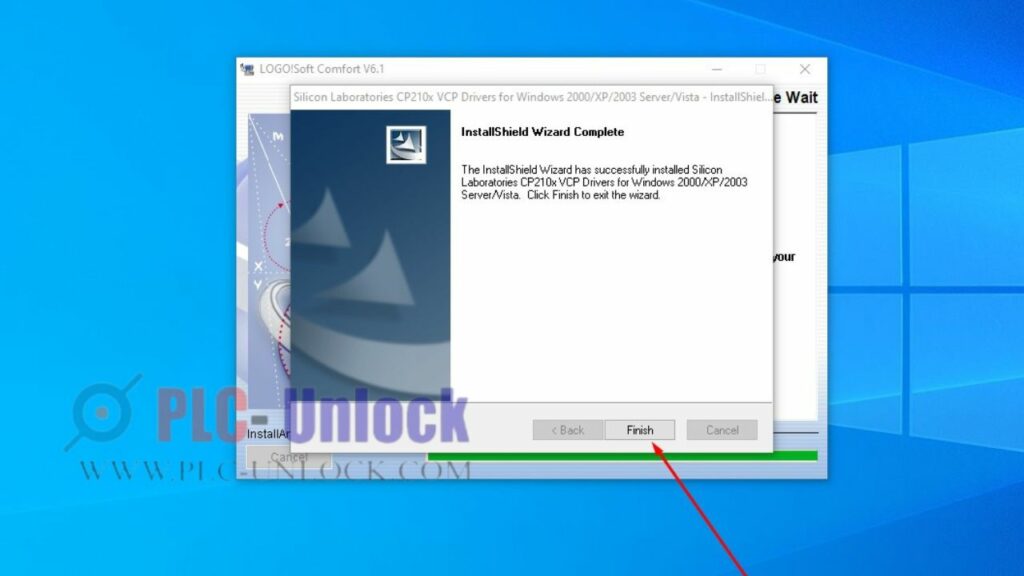

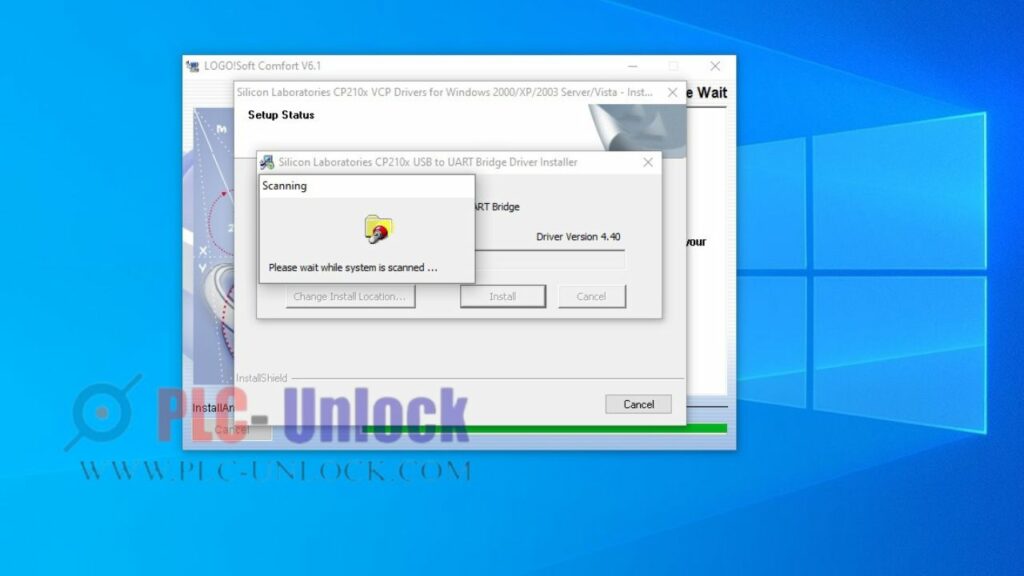

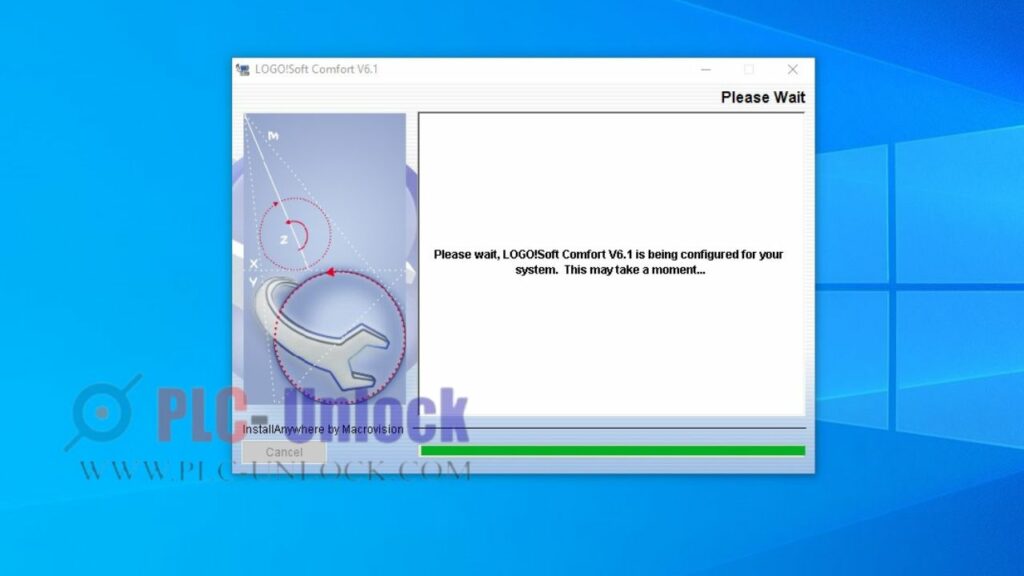

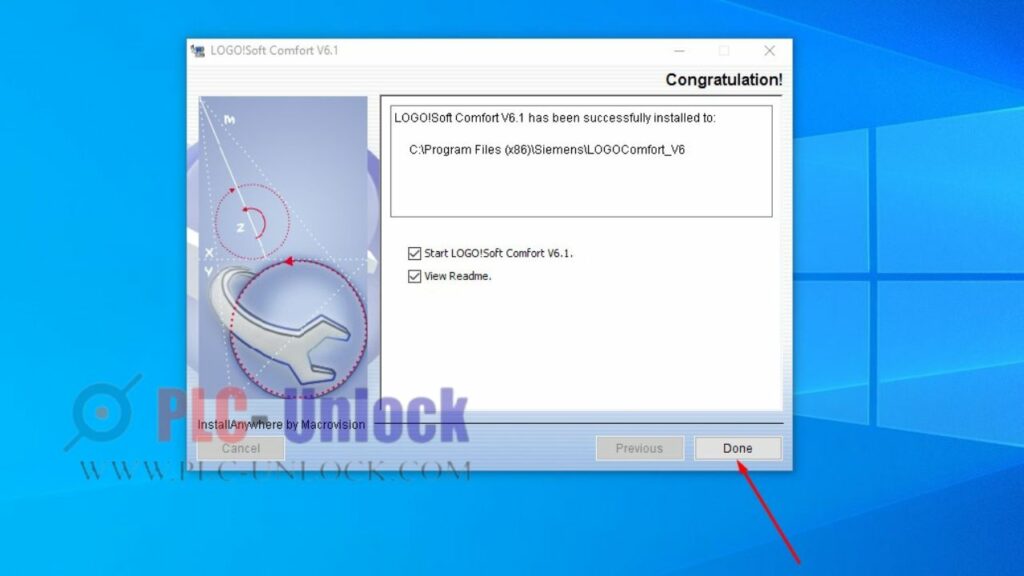

You open your project file victimization step seven

Remove all password

Siemens PLC password break is finish this way; while not on top of instruction, the PLC password crack in a different way.

In Conclusion, The product quality of the programmable Logic Controller is outstanding, and that they were the highest of this position within the late nineteenth century and extremely early within the twenty century.

At constant time, another company has full-grown up, and that they conjointly give the proper merchandise to check low worth than alternative PLC. The programmable Logic Controller password is latch to avoid unauthoriz person interference. that’s the way to Unlock PLC-password